HOW THE COATINGS WORK

The key to the coating’s thermal performance is that it provides increased reflected radiant energy by absorbing that energy and subsequently releasing it back out from the surface

The coating’s reflectivity is also a function of temperature—the coating’s performance actually increases in hotter temperatures.

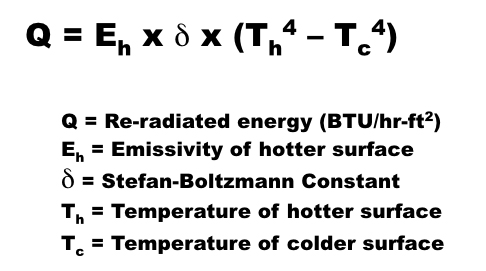

The science of reflectivity:

Comparison of uncoated vs. coated surface:

The surface receives the radiant energy and transmits it back to a colder body. The efficiency with which it achieves this is related to the reflectivity of the surface and the quantity of heat absorbed and re-radiated.

Chemistry:

- The coatings binder system is compatible with all types of refractory as well as all ferrous & non-ferrous metals

- Instead of designing the coatings to have a thermal expansion matching the intended substrate, the binder was formulated to optimize the bond strength between the coating and the substrate

- Under thermal cycling conditions, bonding of the coating to the substrate allows the coating to move with the dimensional change of the substrate thus preventing shearing between the coating and the substrate.

- For the coatings to be effective, the temperature of the coated surface must be hotter than the load or it’s surroundings

ITC Coverage Rates

FIBER LINING

ITC 100HT 1-gallon pail 40 square feet

ITC 100HT pint 5 square feet

ITC 296A 1-gallon pail 50 square feet

ITC 296A pint 6.25 square feet

BRICK LINING IFB (Insulating Fire Brick)

ITC 100HT 1-gallon pail 80 square feet

ITC 100HT pint 10 square feet

ITC 296A 1-gallon pail 100 square feet

ITC 296A pint 12.25 square feet

BRICK LINING or HARD CAST REFRACTORY

ITC 100HT 1-gallon pail 50 - 100 square feet

ITC 100HT pint 6.25 - 12.5 square feet

ITC 296A 1-gallon pail 100 - 200 square feet

ITC 296A pint 12.25 - 25 square feet